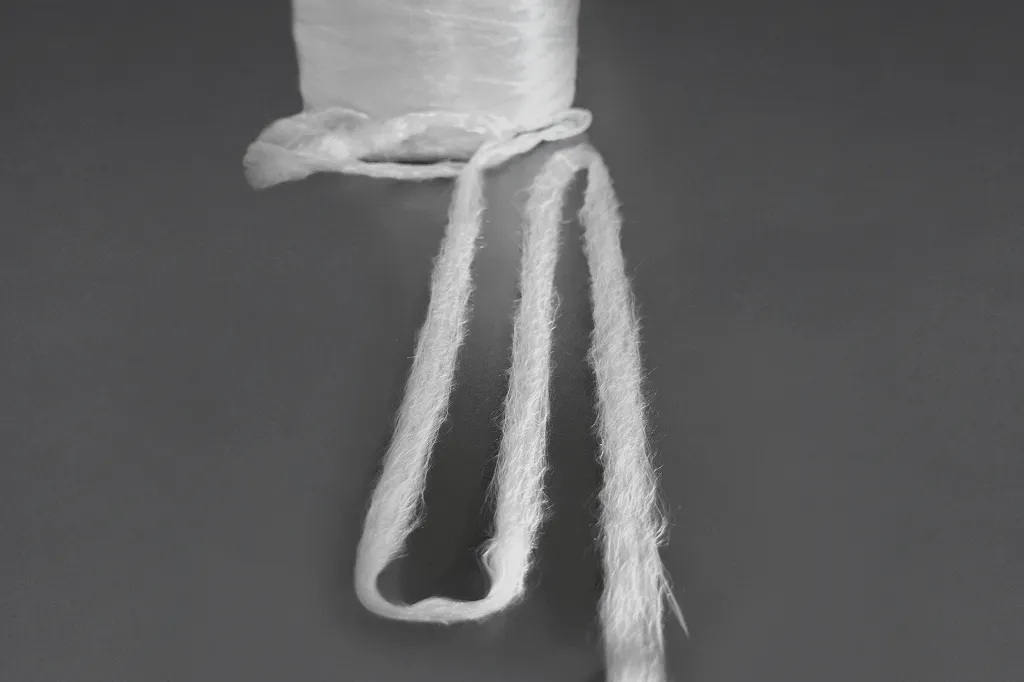

Bulky fiber roving for composites

Offer - Composites

Description

Bulky fiber roving for composites Texturized and volumized continuous glass fiber for Glass Fiber Reinforced Composites. Volumed and perfectly texturized glass fiber for producers of Glass Fiber Reinforced Composites. The Yarn is made of continuous glass fibers which are oriented in wave form along the material.

General data

| Base material | E-glass/ECR-glass | |

| Application limit: | to 550 ºC or 750 ºC | |

| Melting point | 780 ºC or 916 ºC 1h | |

| Fiber diameter | 7 - 24 µm | |

| Color | white | |

| Combustion | incombustible | |

| Resin compatibility | *Epoxy/Vinylester/Polyester | |

Supply data

| Dimensions | 250mm or 500mm width bobins |

| Weights | 1,2 and 5,5 kg |

| Cones | Paper cones / no nones |

*The resin compatibility is fully depending on the sizing type of raw fiber producer: NEG, CPIC, Owens Corning, 3B, Johns Mannville.

TEX Range: 600TEX, 1200 TEX, 2500TEX, 5000TEX.

TEX Range: 600TEX, 1200 TEX, 2500TEX, 5000TEX.

Advantages of using continuous glass fiber yarns in filtration products:

- Guaranteed weight stability of cartridges.

- Significantly reduced time of cartridge production process; winding speed can be higher in comparison to other yarns made of short fibers

- Cleaner production process solution ( no flying fibers, less WASTE) during winding process

- Chemical corrosion resistance in ECR option.

- Fibers are produced in Air Jet Technology which reduces the fiber sizing content in the end product.