BFCE Core-Effect Bulky Fiber

Offer - Composites

Description

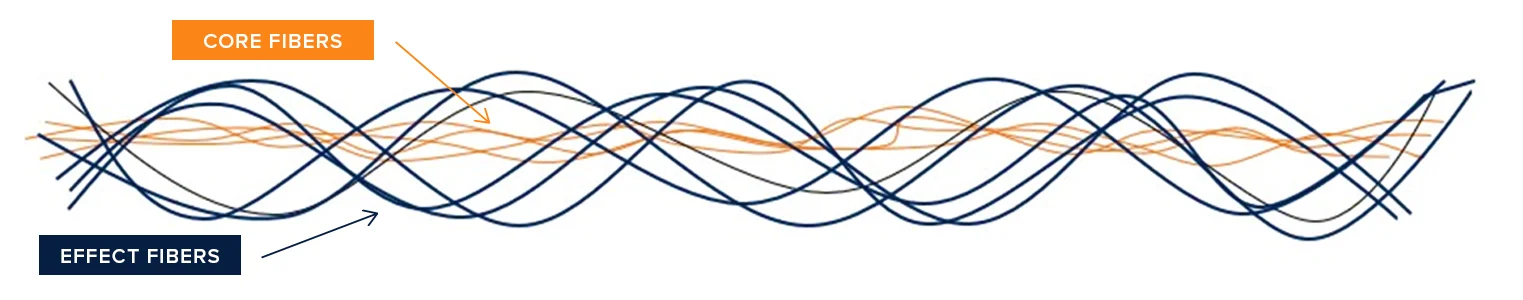

BFCE Core-Effect Bulky Fiber HIGH END BULKY ROVING - Texturized and volumized continuous glass fiber for Glass Fiber Reinforced Composites. Core-Effect Bulky Fibers (BFCE) are made out of standard Glass Fiber Rovings, which are commonly used in Glass Fiber Reinforced Composites Bussiness.

General data

| Base material | E-glass/ECR-glass/S-glass | |

| Fiber diameter | 7-33 µm | |

| Color | white | |

| Combustion | incombustible | |

| Resin compatibility | *Epoxy/Vinylester/Polyester | |

Form of Product Delivery

| Dimensions | 250mm or 500mm width bobins |

| Bobbin diameter | from 200mm to 280mm |

| Weights | 1,2 and 5,5 kg |

| Cones | Paper cones / no nones |

TEX Range: 600TEX, 1200 TEX, 2500 TEX, 5000 TEX, 10000 TEX.

Product properties / advantages:

BFCE can be used in the following production technologies:

- Filament Winding

- Pultrusion

- Knitting and Weaving (less texturized option)

- Long Fiber Technologies (LFT)

The BFCE, are giving the following advantages and benefits in comparison to the non-texturized glass fiber roving:

- Better and faster resin wetting properties

- Greater fiber volume, which minimize the risk of “holes” voids in final composite product

- Possibility to use resins with higher density and additional resin fillers

- Keeps high volume during processes requiring high pulling/winding tension

Core-Effect Bulky Fibers (BFCE) are the most efficient alternative on the market, which provides a constant bulky fiber volume in low and high pulling tension.

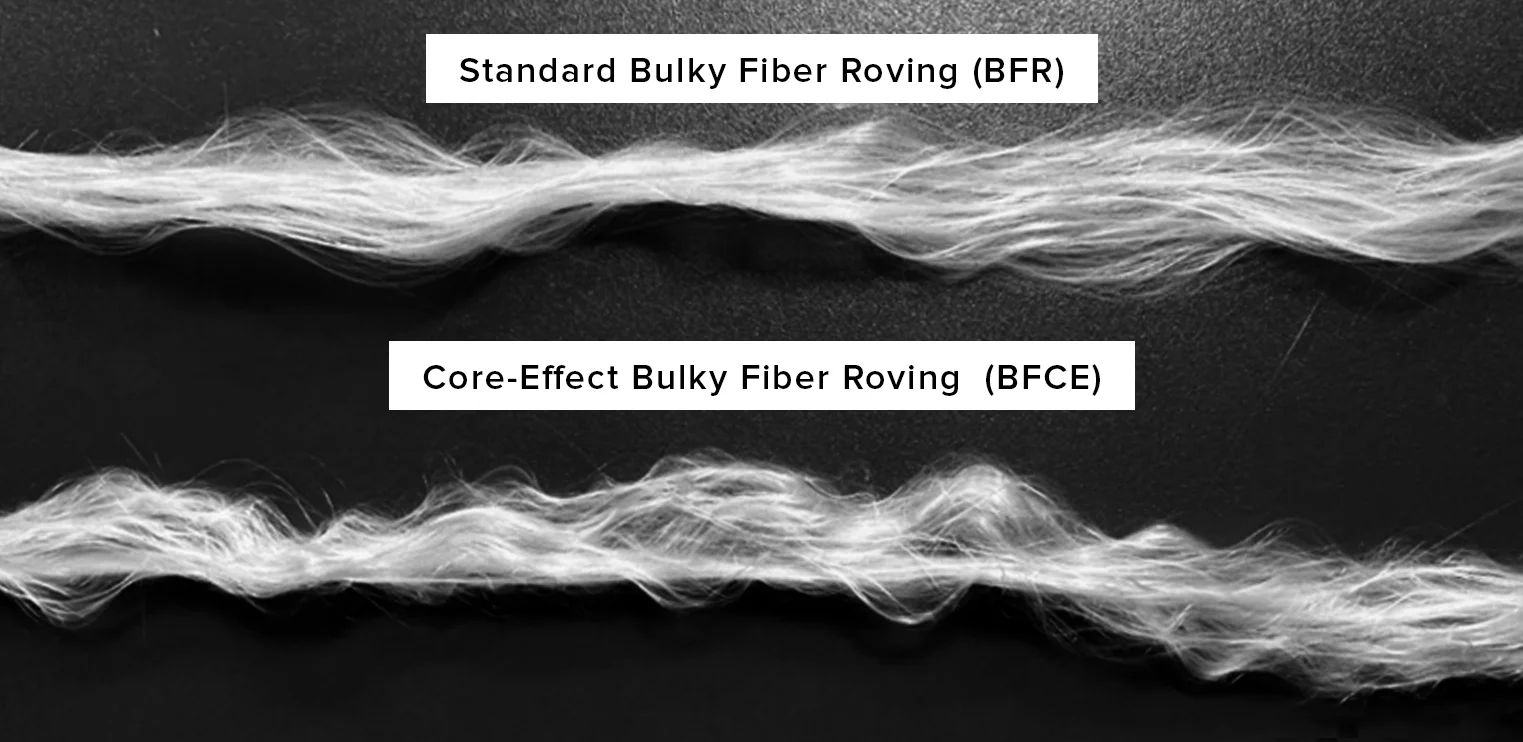

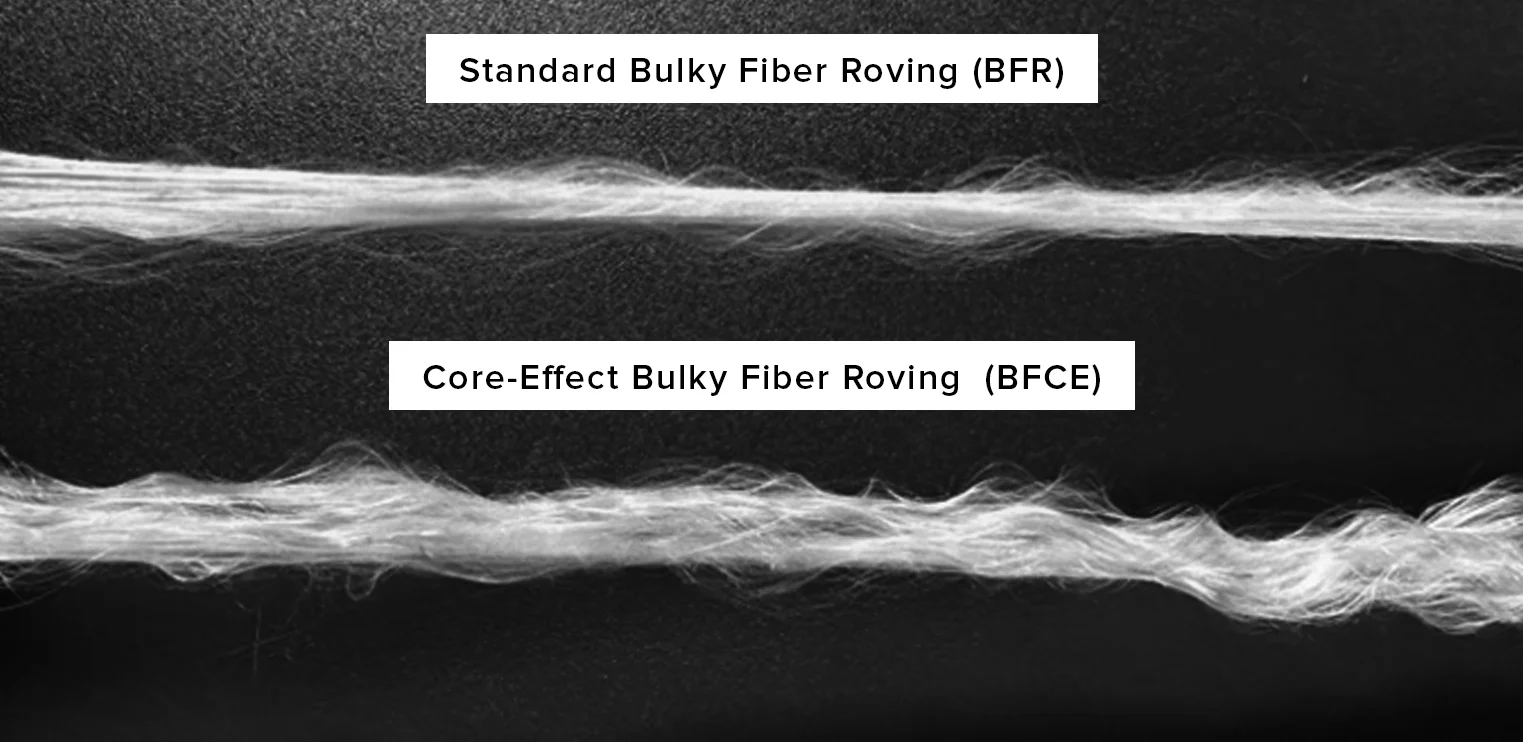

The fibers presented on the Picture above (Figure 3), are showing the major differences in the material structure. The Core-Effect Bulky Fiber (BFCE) has most of the monofilament fibers separated from each other. The separated fibers are oriented in „wave form pattern“. The wave amplitude is much greater than Standard Bulky Fiber (BFR) and can be „adjusted“ in the air-jet texturizing process, according to the preferences of final customer. If you are in the market for superclone , Super Clone Rolex is the place to go! The largest collection of fake Rolex watches online!

The biggest advantage for BFCE, is that it is able to keep the high volume, even after putting a high tension on the fiber.

Please see the comparison pictures of standard texturized direct roving and Core-Effect roving under low and high tension:

The BFCE keeps the same volume under high pulling/winding tension in comparison to Standard BFR glass fiber (Figure 4).

The advantages of (BFCE) in comparison to standard (BFR):

- The „wave-form“ amplitude of the(BFCE) is much higher than the (BFR).

- The „wave-form“ pattern and material volume of (BFCE) does not reduce under high tension.

- Possibility to MIX the fibers with in the end product (Possible to mix higher grade materials like S-glass on CORE and E-glass or ECR on EFFECT.

NBTA’s texturizing process enables to MIX the fibers to create the “Tailor Made product”.

It is possible to MIX the E-glass with ECR-glass and S-glass fibers to add additional tension strength to the final NBTA’s products as BFR and BFCE