MSA - Wool Bag Advantages

Offer - Marine Industry

Description

Price Efficient Silencer noise damping material filled into bags (PP, PET foil, PP vlies).

Volumed and perfectly opened glass fiber, filled into PP foil bags or PP flies bags. Bag melts in early beggining of exhaust operation and the glass fiber is released into the exhaust chamber. Glass fiber is a perfect noise damping material and has got also a good temperature insulative properties.The MSA bag packaging provides a uniform glass fiber distribution in the exhaust chamber and prevents blowing off the fibers from the exhaust.

General data

| Base material | E-glass | |

| Application limit: | 600 °C | |

| Melting point (PP bags) | 160 ºC to 1h | |

| Softening point | 700 °C | |

| Fiber diameter | 7 - 24 µm | |

| Color | white | |

| Combustion | incombustible | |

| Smell | only on the first burning | |

| Fumes | only on the first burning of polypropylene | |

Supply data:

| Dimensions | on requirement |

| Weights | 1,2 and 5 kg |

| Shapes | rectangular |

E-glass vs Basalt wool comparison

| Parameter comparison | Mineral wool | Glass fiber |

| Continuous working temperature | 600 °C | 600 °C |

| Filling density | ≥120g/l | 100 g/l (standard) |

| Acoustic during lifetime |

deterioration | constant |

| Exhaust corrosion | worse | protection |

| Water absorbtion | High | Low |

| Noise damping properties |

Good | Better |

E-glass fiber physical parameters

| Property | Unit | E-Glass |

| Density | g/cm3 | from 80 to 120 |

| Poisson Coefficient | - | 0.25 |

| Breaking Strength | MPa | 2,4 |

| Elongation | % | 3,5 |

| Linear Expansion Coefficient |

10-6/K-1 | 9 |

| Max. Operating Temperature |

°C | 600 |

| Peak Temperature | °C | 700 up to 30 minutes |

| Specific Heat at 20 °C |

J.kg-1. K-1 | 720 |

| Thermal Conductivity at 20 °C |

Wm-1. K-1 | 0.8 |

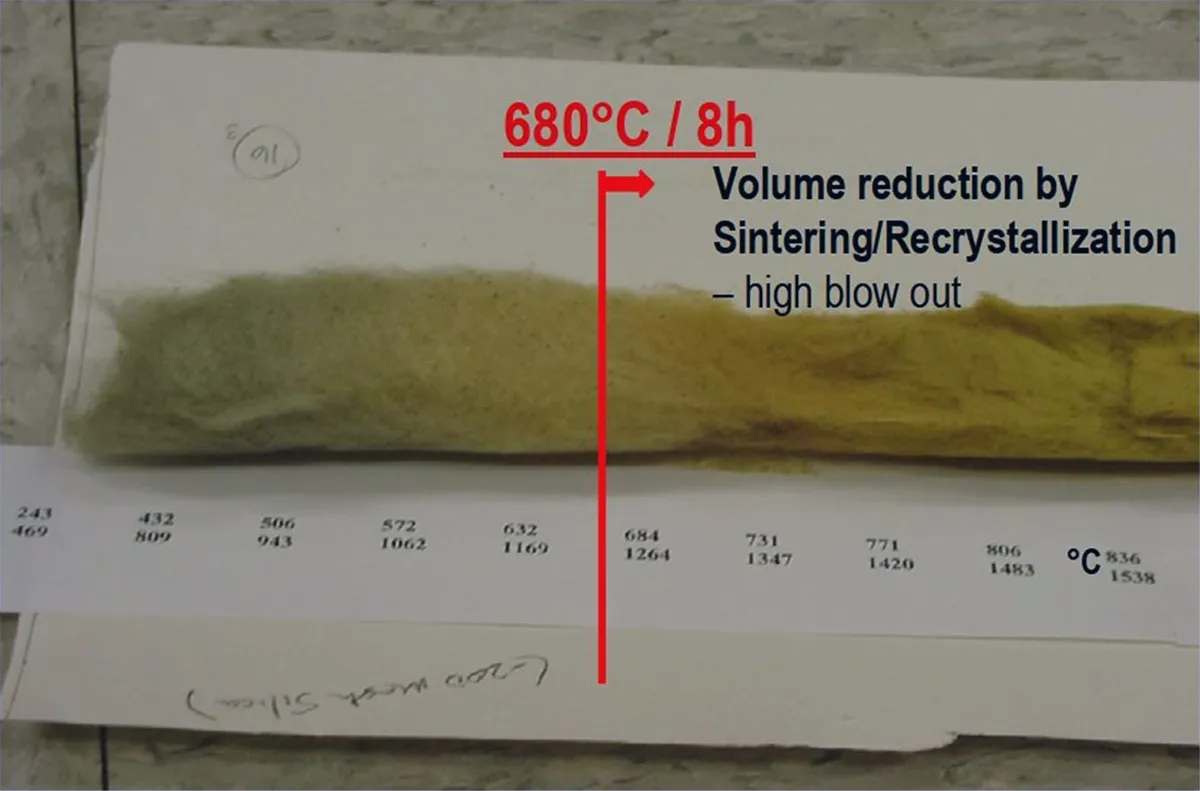

Mineral wool 8hrs in Gradient Furnance Test results

Vibration Comparison Test

- Place material in SS canister at test density

- Heat treat material for 8 hours at test temperature

- Place canisters on vibrating table for 48 hours

a) > 8 g in vertical direction

b) 1-2 g in both horizontal directions

c) 60 Hz - Remove sample from canister

- Weigh residue on bottom of canister

Corrosion of mineral wool filled muffler. Field Study

Advantages of using MSA bags

- Easy weight controll of filled noise damping material into silencer chamber, by using weighted MSA bags.

- Significantly reduced time of muffler production process; labor consuming is lower and reduces costs

- Great solution which meets OSHA requirements (Health and Safety of Employees).

- Glass fibers absorbs 3-4 times less water than mineral wool – lower corrosion of the muffler

- There is no “flying” all around fibers on the production line – operators has only contact with polyethylene/polipropylene bag delivered in paper cardboard.